Formulate and guide the execution of Joint Service initiatives through the integration of technical and business competencies delivering holistic solutions to our customers

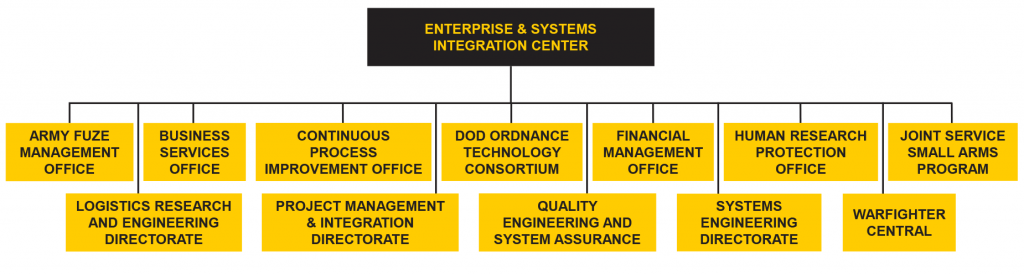

The Enterprise & Systems Integration Center works within the Armaments Center enterprise, providing armaments technology customers with products and services that are under budget, delivered ahead of schedule, and that perform beyond expectations. ESIC serves as the Armaments Center executive agent to ensure cost, schedule, performance adherence and sustainability of Armaments Center projects using consistent processes, utilizing an empowered integrated product team approach, employing best practices which will maximize workforce agility, minimize cost, exceed quality standards and accelerate technology transition to the field.

Please click on the boxes below to learn more about ESIC offices and directorates.

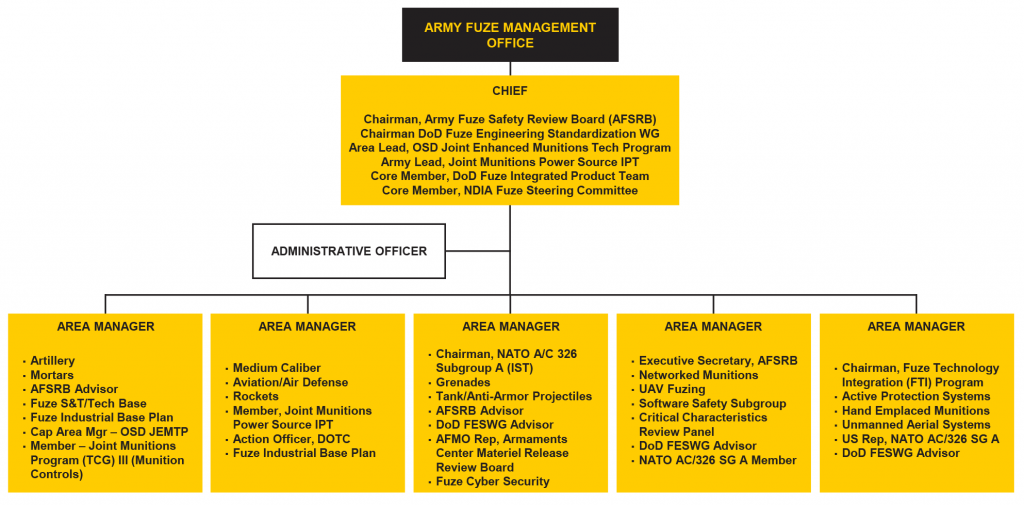

ARMY FUZE MANAGEMENT OFFICE

Provide oversight of fuze technology, fuze standards and fuze design safety involving DoD, industry partners, academia & international partners

The Army Fuze Management Office (AFMO) serves as the primary point of contact within the Army for all fuze developments, approvals, policies and related issues. The AFMO executes centralized across-the-board oversight, selected independent studies on fuze technologies and industrial base assessments, and management of select Army fuze and safe & arming (S&A) programs throughout the life cycle. Oversight includes promoting the advancement of and efficient transition of fuze and S&A technologies capable of supporting Army modernization priorities and maintaining cognizance and participating in decisions during fuze research and development, production, sustainment, and demilitarization.

The AFMO manages and chairs the Army Fuze Safety Review Board (AFSRB), exercising sole authority for providing safety approval of all fuzes and S&As developed, procured and used by the Department of the Army. The AFMO advises and provides guidance to program executive offices (PEO), project managers and other managers, maintains oversight and provides assessments and recommendations at milestone reviews. Managers within the PEO and non-PEO materiel development organizations within the Army must include the AFMO in integrated product teams and coordinate their fuze plans and needs with the AFMO at the appropriate decision points as delineated in this charter.

Serve as the focal point for Army fuzing in tri-service and international safety and interoperability standardization matters and materiel activities and actions.

Contact the Army Fuze Management Office at : usarmy.pica.devcom-ac.mbx.afsrb@army.mil

BUSINESS SERVICES OFFICE

Provide administrative and operational support to ESIC. Complete personnel transactions, management, facility support and other mission support activities. Coordinate actions of assigned administrative personnel

- Provide direct business support to the Enterprise and Systems Integration Center (ESIC). Provide administrative support to headquarters and divisions and co-located on-site support, as required.

- Coordinates and execute administrative data management and procurement support/liaison functions. Data management documentation process includes Tables of Distribution and Allowance, position descriptions and other personnel management data.

- Perform human resources, operational review and analysis functions

- Implement command policy and procedures for the center in administrative support areas to include timekeeping, personnel transactions, training, evaluation, awards. Provide detailed support of training management function to include scheduling, payment, course evaluation and planning. Coordinate the efforts of all administrative support assigned to ESIC to ensure continuity of command policies and procedure.

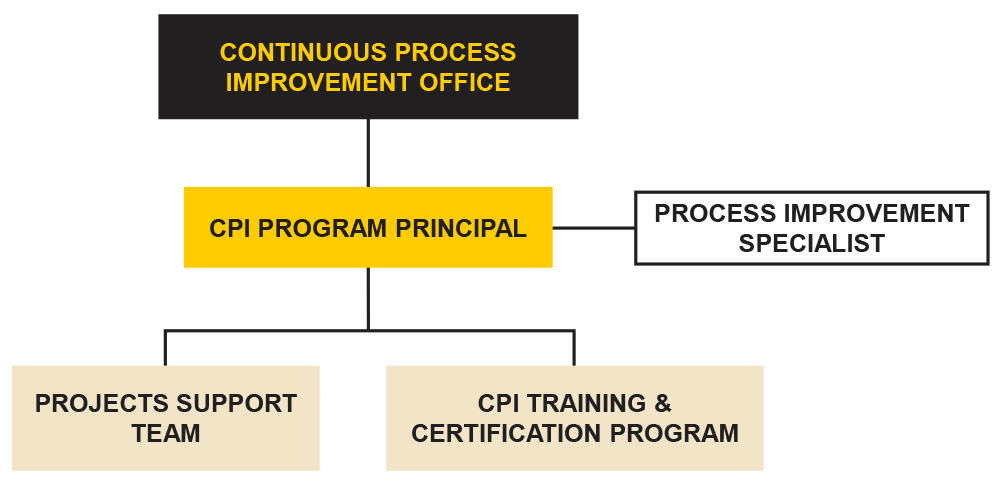

CONTINUOUS PROCESS IMPROVEMENT OFFICE

Deliver a comprehensive continuous process/performance improvement program at the Armaments Center and JPEO A&A that drives innovation and modernization, expands workforce knowledge, and fosters a culture focused on effectiveness and efficiency improvements

The Continuous Process Improvement (CPI) Office is committed to all continuous performance/process improvement efforts for a full spectrum of customers enabling the Armaments Center to serve as the benchmark for efficiency and effectiveness beginning in science and technology and extending throughout the acquisition lifecycle. The Armaments Center and Joint Program Executive Office for Armaments and Ammunition (JPEO A&A) share robust and well-defined Lean Six Sigma, value engineering, and continuous process/performance improvement programs.

The CPI office manages the performance and reporting of the joint Armaments Center/JPEO A&A CPI Program in accordance with DoD Office of Management and Budget Circular A-131; Army Regulation 5-1, Management of Army Business Operations; and Army Business Process Improvement Deployment.

The CPI Office represents the Armaments Center and JPEO A&A at the Army Value Engineering Functional Working Group and the Army Futures Command Business Process Improvement Executive Steering Committee.

The CPI Office provides the expertise and associated competency for execution of the following:

- Value Engineering Proposal development, Value Engineering study, analysis and reporting

- LSS green belt, black belt, and master black belt training and refresher training

- Project selection, consultation, mentoring and certification of the workforce

- Kaizen, lean activities, lunch and learn, master black belt/black belt community of practice

- Joint Armaments Center and JPEO A&A Lean Six Sigma Review Boards

- CPI recognition programs

- Industry and best practices from other government agencies

Our practitioners are committed to supporting project work sessions, implementation and deployment in the following areas:

- Technical

- Business/transactional

- Managerial

- Engineering

Lean/Six Sigma/Design for Six Sigma methods, value engineering and other process improvement best practices serve as the foundation for Department of Defense Better Buying Power and continuous improvement initiatives across the acquisition lifecycle. The Armaments Center & JPEO A&A CPI Office is located at Picatinny Arsenal, New Jersey. The office is composed of master black belts and black belts who are responsible for planning, development and execution of Armaments Center/JPEO A&A missions.

HUMAN RESEARCH PROTECTION OFFICE

- The Human Research Protection Office manages the Armaments Center’s Human Research Protection Program (HRPP), an ethical and federal regulatory program charged with the protection of research volunteers as required under Armaments Center’s DoD and HHS Federal-Wide Assurances. The Armaments Center HRPP is structured with three tiers: a) Education and Training; b) Institutional Review Board Review; and c) Oversight/ Monitoring.

- The Armaments Center has established a fully resourced HRPP to provide a mechanism to protect the rights and welfare of all persons volunteering as human research subjects. The requirements in this plan and all Armaments Center policy and procedure documents are specifically directed toward the human research activities covered by this HRPP. The Joint Ethics Regulations Department of Defense Directive 5500.07 apply in general to all federal workers including those engaged in human research and they will remain in effect at all times in addition to the additional ethical research standards, and regulatory requirements included in this plan. The Armaments Center HRPP operating through the Human Research Protection Office has been established for this purpose. For more on the Armaments Center Human Research Protection Program, see HERE

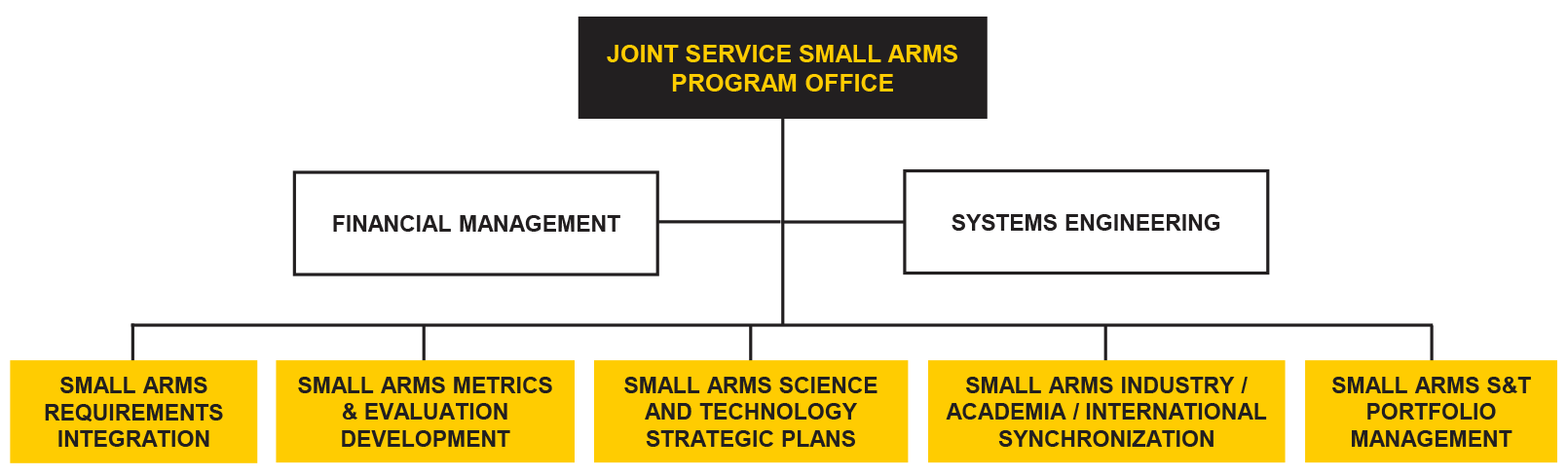

JOINT SERVICES SMALL ARMS PROGRAM

Deliver decisive lethality overmatch to the Joint Service Warfighter through development of state-of-the-art science and technology, reduce project manager risk to acquisition and inform harmonized DoD requirements toward capability gap closure through exploration, characterization and technological ideation.

Bottom Line

- JSSAP develops, resources and executes the Army and DoD small arms science and technology investment strategy.

- JSSAP is the primary source for Joint Service small arms technology investments that harmonizes and creates efficiency for the DoD.

Contact the Joint Service Small Arms Program Office at usarmy.pica.futures-cmd.mbx.jssap@army.mil

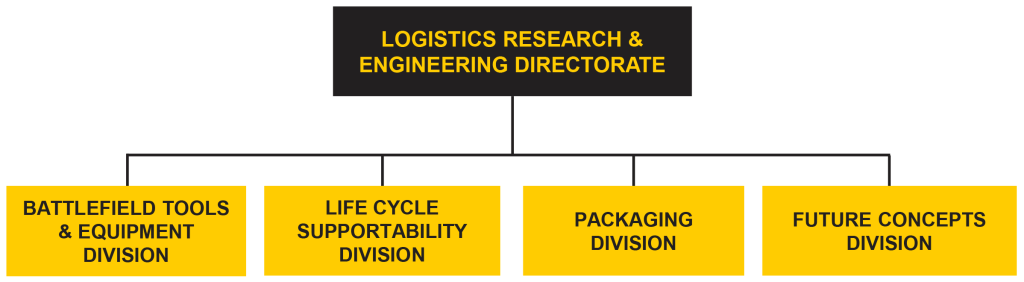

LOGISTICS RESEARCH & ENGINEERING DIRECTORATE

- Serve as lead agent for the Office of the Secretary of Defense, to coordinate research, development, test, and evaluation programs within the military services to improve the safe and secure distribution of arms, ammunition and explosives to the Warfighter.

- Serve as the United States of America Head of Delegation to the NATO Interservice Ammunition Working Group, enabling ammunition interchangeability for NATO coalition forces.

- Serve as the Department of the Army lead to conduct ammunition malfunction investigations.

- Analyze user needs and plan, manage, and implement technology solutions to improve the Army’s ammunition logistics system in each of the following thrust areas: battlefield rearm, munitions packaging, explosives safety/insensitive munitions, logistics C4, combat service support and logistics analysis.

- Manage the development and demonstration of insensitive munitions (IM) technologies to improve the survivability of munitions against unplanned stimuli.

- Provide maintenance engineering, integrated product support management, technical publications, provisioning, and new equipment training for the total life cycle of Army armaments (gun, ammunition, and fire control). Perform life cycle engineering for the packaging of Army armaments (gun, ammunition and fire control).

- Perform life-cycle engineering of Army and U.S. Marine Corps maintenance equipment including common sets, kits, and outfits and tools. Serve as the ammunition logistics division chief for the Product Director Joint Services.

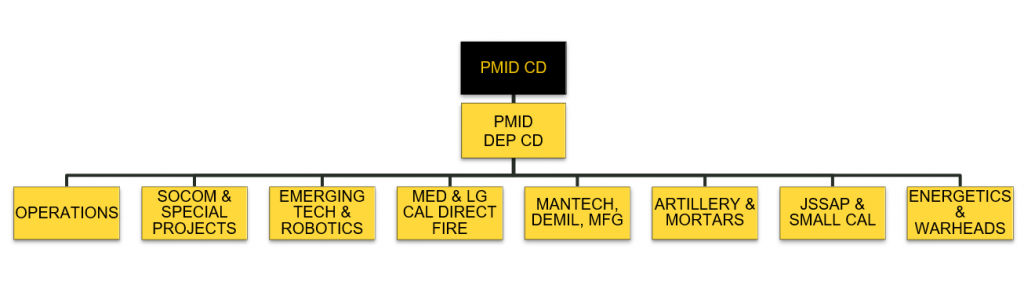

PROJECT MANAGEMENT & INTEGRATION DIRECTORATE

Institutionalizes the project management competency throughout the Armaments Center enterprise. Ensures the effective & efficient management of cost, schedule, performance and risk on all direct and customer funded projects across the acquisition life cycle in accordance with DOD 5000 and USSOCOM Directive 70-1.

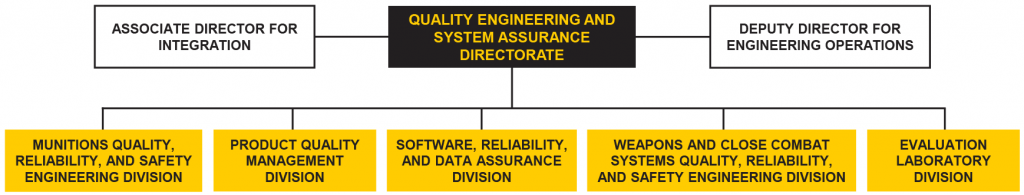

QUALITY ENGINEERING & SYSTEM ASSURANCE DIRECTORATE

Our Warfighters know their armaments perform-First Time, Every Time

The Quality Engineering and System Assurance (QE&SA) directorate brings over 50 years of experience executing and managing an integrated life-cycle quality and system assurance program required for the research, development, production, field support and demilitarization of ammunition, weapons, fire control and associated items. QE&SA, through participation on all Integrated Product Teams, provides project officers, designated project/product managers and other customers with essential technical competencies which assure systems and components are safe, reliable and perform as intended.

The QE&SA organization is structured around functional areas with the goal of developing and maintaining a world-class workforce with a controlled, repeatable process for achieving enterprise excellence. QE&SA consists of five divisions: Munitions, Weapons and Close Combat Systems, Product Quality Management, Software, Reliability and Data Assurance, and Evaluation Laboratory. These divisions, in conjunction with QE&SA headquarters, administer day-to-day oversight and execution of the directorate’s mission, and are responsible for delivering products and services to customers. Collectively these principals form the QE&SA Quality Steering Group (QSG), providing the strategic direction for the organization.

While its five division chiefs manage QE&SA resources, core competencies are managed by deans, providing the technical foundation for organizational excellence. QE&SA core competencies are:

- Quality Engineering

- Reliability Engineering

- Product Quality Management

- Software Quality, Reliability and Safety Engineering

- Product Verification and Validation

To ensure consistent, repeatable performance to its customers, the Directorate utilizes processes and controls consistent with internationally recognized management models such as ISO 9001, Lean Six Sigma, Visual Workplace, and daily Continuous Process Improvement. Additionally, QE&SA has partnered with WSEC in the Armaments Center Software Engineering Center to achieve and maintain Capability Maturity Model – Integration (CMMI) Level 5 certification.

QE&SA continues to explore opportunities to innovate and leverage best practices to enhance its competency portfolio and the quality of goods and services it provides to its government and industry customers.

CORE COMPETENCIES

- Quality Engineering

- Reliability Engineering

- Product Quality Management

- Software Quality, Reliability and Safety Engineering

- Product Verification and Validation

FACILITIES

QE&SA Special Functions

Materiel Release

The Armaments Center Materiel Release Program implements the Department of the Army’s Materiel Release policy and requirements established in AR 770-3 (Type Classification and Materiel Release) to assure that materiel is safe, operationally suitable and logistically supportable before being issued to the troops. The Materiel Release process provides formal and disciplined management controls for the review and evaluation of materiel systems to assure that these systems comply with all applicable requirements prior to release for field issue, and that a suitable audit trail is established and maintained.

Standardization

The Armaments Center Standardization Office within QE&SA manages the implementation and execution of the policies and procedures identified of the Department of Defense Domestic Standardization Program and implementing Army Guidance.

Critical Characteristics Review Panel (CCRP)

The CCRP is charged by DEVCOM Armament Center Policy to conduct a formal review of all government technical data classification decisions for critical characteristics and make recommendations for their approval or disapproval. CCRP review is conducted in support of well-developed and mature Technical Data Package (TDPs) for procurement purposes. In accordance with AC Critical Characteristics Policy, all Government technical data that contains critical characteristic(s) undergoes a technical review by the Critical Characteristic Review Panel (CCRP) for assessing the proper classification and declassification of critical characteristics and inspection method prior to release. Its review by a panel of cross-function and cross-commodity independent technical experts is done in order to promote accuracy and consistency in the classification and documentation of critical characteristics for armament and munitions systems.

Detail Specification Review Panel (DSRP) and Performance Specification Review Board (PSRB)

The mission of the DSRP is to promote accuracy and clarity of detail design requirements and verification methods in Detail specifications for detailed designs and Technical Data Packages (TDPs); the mission of the PSRB is to promote accuracy and clarity of performance design requirements and verification methods for performance specifications, particularly for performance-based acquisitions. For both the DSRP and PSRB, specifications are reviewed for technical maturity, clearly defined requirements and basis for acceptance, appropriate inspection and verification methods, acceptance provisions, and proper classification of characteristics. The DSRP and PSRB, comprised of independent subject matter experts, is responsible for reviewing every new or revised specification that is processed through standardization to provide technical recommendations for the supported programs ensuring that these technical documents are robust, technically suitable, and clear to the Government and industrial base partners.

SYSTEMS ENGINEERING DIRECTORATE

We apply systems engineering expertise at the cutting edge ensuring efficient delivery of effective armaments and warfighter capabilities

FUNCTIONS

- Provide armaments systems engineering expertise supporting the lifecycle of Armaments Center activities to include requirements engineering, architectural analysis and design, interface development and management, technical planning and assessments, system-of-systems analysis, decision analytics and configuration and product data management. Leverage domain expertise across the Armaments Center portfolio to ensure we provide quality systems engineering products and services to support technical and programmatic decisions throughout the lifecycle of the effort.

- Lead technical planning and implementation activities through the Armaments Technology Development Process.

- Structure and deliver accurate and timely armaments systems engineering artifacts to our customers to support fact-based decisions with a full understanding of the associated benefits and risks.

- Develop and implement cutting-edge armaments systems engineering best practices, tools and workforce development activities to ensure effective and efficient systems engineering execution in support of the Armaments Center mission.

- Serve as a member of the greater DoD Systems Engineering Community, to include the Office of the Secretary of Defense, Assistant Secretary of the Army for Acquisition, Logistics and Technology, other DEVCOM centers and the Systems Engineering Research Centers to research and influence systems engineering policies and procedures.

- Apply armaments systems engineering expertise to non-traditional areas to actively create partnerships beyond the lethality domain and deliver enduring value to new and existing customers.

- Leverage the Collaborative Armaments System Integration Laboratory to enable Armaments Center mission success through systems-of-systems integration activities, joint distributed simulations and hardware/software in-the-loop evaluations.

WARFIGHTER CENTRAL OFFICE

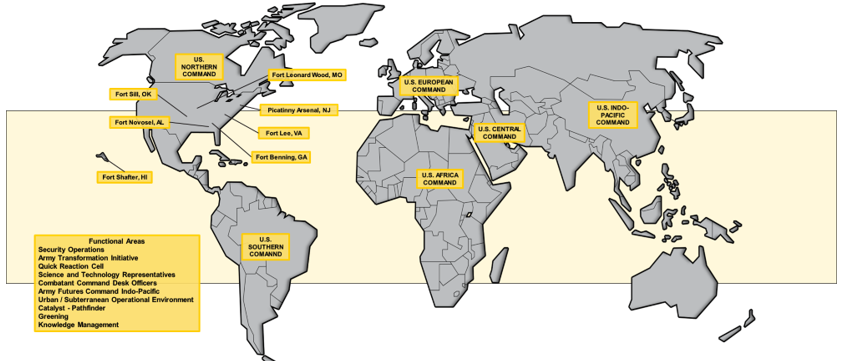

Fuse operational context, global threat intelligence and emerging requirements to inform technologies and products that meet Warfighter needs throughout continuous transformation

Warfighter Central supports both the operational and institutional Army with locations in both the continental and outside the continental United States with centers of excellence, capability development integration directorates and combatant commands across concepts, requirements, experimentation and integration.

Warfighter Central increases the Armaments Center’s relevance to our warfighter by providing: greening training for all Armaments Center employees so they better understand how our Warfighters use our products; maintaining liaison with U.S. Army Training and Doctrine Command centers and schools to ensure our products meet mission requirements; strategic foresight analysis of social, technological, economic, environmental, and political trends and thrusts to better inform our long-term view of warfighting and technology availability, and management of the Armaments Center’s junior military to ensure their support is provided to critical enterprise products/functions. To better enable these functions, Warfighter Central also maintains liaison with West Point.

E-mail Warfighter Central at: AFC-DEVCOM-AC-WFC-RFI@army.mil