Research, develop and engineer technologies for software and weapon systems that provide overmatch capabilities to those who defend our nation now and in the future.

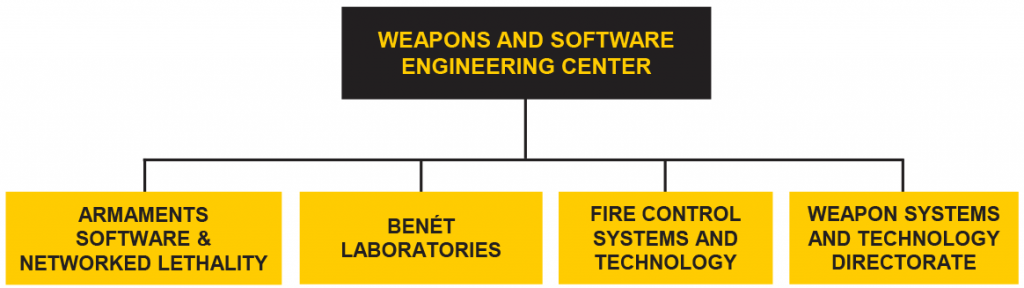

The Weapons and Software Engineering Center generates technologies and executes life-cycle research, design development, engineering, production engineering and sustainment of national and international standardizing programs related to weapons and weapon systems. It maintains and grows core competencies capable of full spectrum support to all current and future weapon systems.

Please click on the boxes below to learn more about WSEC’s organization.

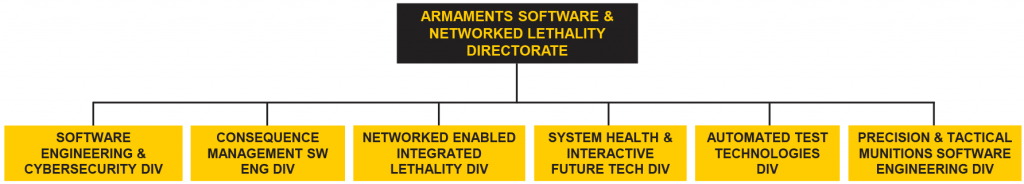

ARMAMENT SOFTWARE AND NETWORKED LETHALITY DIRECTORATE

The Armament Software and Networked Lethality Directorate (ASNLD) is recognized as DoD’s foremost provider and the Army’s lead for technical and programmatic life cycle engineering (research, development, sustainment and field support) efforts for network lethality tactical fire control solutions for fires and effects based operations via distributed/common network architecture, threat awareness systems for installation emergency management and response, force protection, precision and tactical munitions software engineering, automated test and system health technologies, predictive logistics, cybersecurity engineering and assessment, interactive and multi-media technologies for virtual prototyping and training to equip, modernize and sustain the Joint Forces.

The ASNLD occupies a mission space of great responsibility, capability, scope, and scale. The defense industrial base demonstrates an increasing reliance on software to manage complex systems. Software is ubiquitous in DoD systems embedded in space-based, air, ground, sea, sub-surface, and subterranean platforms to individual soldier weapons, devices, and sensors as well as all echelons of command and control, communication and intelligence. As domains, systems and technologies merge, ASNLD is poised to modernize its practices as the Army modernizes how it delivers software.

The ASNLD provides the Soldier, Army, DoD and other customers a center of excellence for software engineering and software acquisition support services for weapon systems, training devices, and combat support systems throughout the entire system life cycle. Our software acquisition practices align with the Adaptive Acquisition Framework (DoDI 5000.02, 23 JAN 2020) and the Software Acquisition Pathway (DoDI 5000.87, 02 OCT 2020). Our software engineering methods and processes are in accordance with the DoD Software Modernization Implementation Plan (30 MAR 2023) and Army Directive 2024-02: Enabling Modern Software Development and Acquisition Practices (11 MAR 2024). We are the steward of the Armaments Center Software Factory, a cloud-based DevSecOps environment for the continuous development, integration and deployment of software systems. ASNLD continues to support legacy systems following more traditional models of system and software acquisition as required to meet customer needs. We are investing in modern software development toolsets and training our staff in modern software development implementation methodologies demonstrating our commitment to key performance enhancement initiatives while leveraging our traditional model-based improvement.

Assigned mission includes kinetic threat defeat (e.g., target threat acquisition, identification, classification, tracking and neutralization capabilities), integrated base defense, anti-terrorism/force protection systems, decision-support, sensor-to-shooter, sensor-to-decider, small unit manned/unmanned effects teaming, precision and tactical munitions software, cybersecurity engineering and assessment, intelligent control and collaboration technologies, armaments virtual prototyping, operator and maintenance training systems.

CORE COMPETENCIES

LIFE CYCLE SOFTWARE ENGINEERING

DevSecOps Ecosystems/Armaments Center Software Factory

- Modern Source Control, Branching and Merging Strategies

- Automated Development & Build Pipelines, Continuous Integration, Testing, and Scanning

- Containers / Container Orchestration

- Platform as a Service (PaaS)

- Government Cloud Services

- Software Technical Data Package Baselines and Release Management

Software Process & Performance Improvements

- Modern Software Engineering Practices

- Agile Methodologies

- Defined & Repeatable Organizational Standard Processes

- Performance Metrics

- Compliance & Deviation Detection

Software Modular Open Architecture

- Reference Architecture (RA)

- Open Application Programming Interfaces (API)

- Interoperability Standards

- Data Models/Schema

Software Acquisition Support

- Software Considerations for Contracting

- Contractor Oversite – Evaluation of Contractor Deliverables, Progress, and Risk

- Organic Software Support Beyond Fielding

CYBERSECURITY

Cybersecurity Engineering

- Acquisition Cybersecurity Strategy (CSS) Development

- Cyber Survivability and Architecture Design

- Secure Technical Implementation Guide (STIG) Configuration

- Appointed Certified Cyber Roles (Information Systems Security Management (ISSM) / Information Systems Security Officer (ISSO) / Information Systems Security Engineer (ISSE)

- Risk Management Framework (RMF) Authority to Operate (ATO) Support

Cybersecurity Assessment

- Blue Team / Cooperative Vulnerability Penetration Assessment (CVPA) Support

- Software Assurance (SwA) Scanning and Analysis

- Security Control Assessor Validations (SCA-V)

- Vulnerability Scanning and Risk Assessment

Networked Lethality Command and Control Applications

- Fires Planning, Coordination, De-confliction and Execution

- Data Fabric, Cyber Situational Understanding

- Tactical Assault Kit (TAK) Extensions/Plug-ins

- Decision Aids and Planning Tools

- UXS Collaborative Engagement

- GPS Denied Situational Awareness

Chemical/Biological Defense and Warning Systems Software

- Chemical Biological Radiological Nuclear (CBRN) System Software Program Management and Lifecycle Engineering

Mission Assurance and Emergency Management Software

- Installation Common Operating Picture

- Mass Warning and Notification

- E911

- Mission Assurance Common Operating Picture

Precision/Tactical Munitions

- Precision Aerial Delivery Systems Software

- Precision Guided Munitions (PGM) Software

- Networked Munitions Software

- Smart Munitions Software

Automated Test Technologies

- Off Platform Diagnostics for Army Ground Platforms

- Lifecycle Engineering for Automated Test Equipment

System Health Technologies

- Platform Health Management

- Embedded and At-system Diagnostics

- Software Installers and Data Off-loaders

- Virtual Environments (Simulators/Emulators)

- Prognostics and Predictive Maintenance / Predictive Logistics / Contested Logistics

Augmented and Virtual Reality Technologies for Maintenance and Training

- Interactive Virtual Prototype Development

- Game-based Warfighter Trainer Development

- Video Production

FACILITIES

- Advanced Munitions Software Engineering Facility

- Armament Center Software Factory

- Multi-Domain Fire Control Software Laboratory

- Precision Control Unit Software Integration Laboratory

- Swarm Computation and Artificial Intelligence (SCAI) Lab

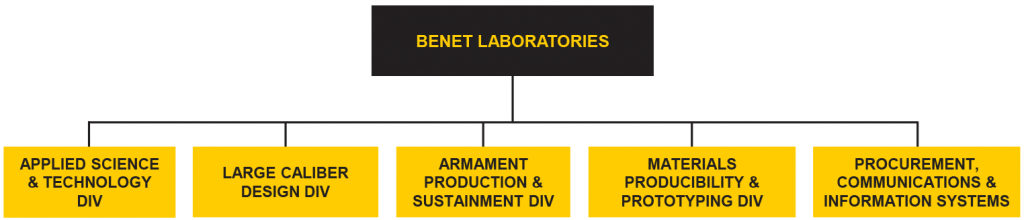

BENÉT LABORATORIES DIRECTORATE

Benét Laboratories Directorate has full engineering responsibility, and subject matter expertise, for the Army’s large caliber cannon systems, encompassing design, production, and lifecycle support. Benét Laboratories maintains the technical expertise for cannon design, including tube, breech, and direct fire recoil mechanisms. Benét is also responsible for mortar weapon system design and development, including the cannon, bipod, and baseplate. All large caliber cannon systems are tested in Benét’s Fatigue Laboratories to establish a safe fatigue life/safe service life. Large caliber cannon production is advanced through development and implementation of advanced manufacturing technologies, developed within Benét and transitioned to the organic industrial base. Weapon systems are then supported throughout production and into the field and supported by sustainment engineering. Benét partners with program managers and TACOM Integrated Logistics Support Center to ensure these systems are lethal, reliable, and producible to provide overmatch capabilities to the warfighter. As the home of tank cannon, artillery and mortar design, development and sustainment engineering, Benét Laboratories provides battlefield dominance to the U.S. Army.

CORE TECHNICAL COMPETENCIES

Large Caliber Cannon Products & Designs

- Indirect Fire Systems & Howitzers

- Direct Fire Systems

- Mortar Cannon Systems

- Recoilless Rifles

- Direct Fire Mounts & Recoil Mechanisms

- Automation, Breech Actuation, Cannon Controls

- Recoil Mechanism Design

- Large Caliber Cannon Material Solutions

- Design and Mitigation for Blast Overpressure, Impulse Noise

- S&T for the Advancement of Large Caliber Cannon Research Thermal Management

Large Caliber Cannon Life Cycle Management

- Engineering Support in Production to Organic Industrial Base (OIB)

- Fatigue and Fracture of Materials Engineering and Analysis

- Dynamically Loaded Pressure Vessel Design, Dynamic Modeling & Simulation, Experimentation, and Validation

- Sustainment of Large Caliber Cannon Armaments

- Large Caliber Cannon Health Monitoring

- Safe Service Life Determination

- Armament Conception and Realization

- Cannon Malfunction Investigation

Manufacturing & Materials Technologies

- Novel and Advanced Manufacturing Technology Development and Insertion

- OIB Production and Manufacturing Process Improvement

- Materials Engineering, Evaluation and Analysis

- Advanced Materials, Computational Design & Modeling

- Advanced Bore Coatings, Wear & Erosion Development & Evaluation

FACILITIES

- Prototype Machine Shop

- Rapid Prototyping Lab

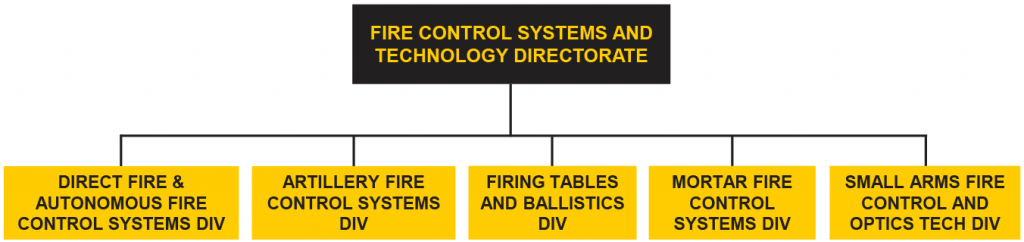

FIRE CONTROL SYSTEMS AND TECHNOLOGY DIRECTORATE

The Fire Control Systems & Technology Directorate (FCSTD) is the Army’s lead for technical and programmatic life cycle engineering (research, development, manufacturing science and production, sustainment and field support) efforts for armament fire control systems to include associated training and simulation, and automated test systems. FCSTD is a recognized DoD’s provider of fire control solutions and technologies to equip, modernize and sustain the joint forces. Assigned armament systems include those used for artillery, mortars, infantry/soldier-borne, combat vehicle, air defense and aircraft weapons systems; and off-carriage fire control instruments and sights and training devices. Associated fire control functionality covers the entire target engagement cycle to include target acquisition and tracking, target/environmental sensing, ballistic computation, gun/launcher/sight control and stabilization, munition initialization/tracking, and network communications; and include diagnostics, prognostics and training capabilities. The Directorate’s Automated Test Division functions as the TACOM ATS Center of Excellence to develop, field, and sustain Automatic Test System products, including Test Program Sets in support of weapon systems for Army and DoD elements and provide associated engineering support. Our Firing Tables and Ballistics Division is assigned by the U.S. Army Materiel Command with the responsibility to characterize the ballistic performance of munitions and develop aiming data, ballistic fire control information and ballistics fire control software for all unguided and certain guided combat weapon systems in U.S. Army inventory, tri-service systems, and foreign military sales cases. To ensure that the organization is flexible and responsive to future demands and needs of internal and external customers, the Directorate uses innovative business practices and processes to include Capability Maturity Model Integrated Level 5 processes and procedures for its in-house fire control development efforts. We satisfy user needs in a timely manner and deliver cost effective fire control solutions by shaping our mission-focused core competencies with a highly educated and experienced workforce, state-of-the-art facilities and equipment, and through use of effective and efficient operations and processes. We contribute to the Armaments Center’s enterprise culture by cultivating a positive workforce climate focused on mission.

CORE TECHNICAL COMPETENCIES

Mortar Fire Control Systems

- Embedded Mortar Fire Control Software Development & Test

- Mortar Fire Control Systems Development & Integration

- Variable Message Format (VMF) Communication & Interoperability

- Optical Fire Control Design & Development

- Precision Guidance Fire Control Systems

Artillery Fire Control Systems

- Digital Fire Control Embedded Software Development & Test

- Digital Fire Control Hardware Development & Test

- Optical Fire Control Design, Development & Test

- Fire Control Systems Integration & Test

- Survey Systems Design, Development & Test

- Ancillary Fire Control Component Integration

Direct Fire and Uncrewed Autonomous Fire Control Systems

- Full Lifecycle Engineering Support

- Armored Vehicle Fire Control (M1A2, XM30, Booker, Stryker)

- Aviation Fire Control (Apache H)

- Fire Control Integration

- Configuration and Technical Data Package (TDP) Management

- Product Improvement Development Efforts (SepV3 SepV4) Modeling and Simulation Production Support

- Multiphysics Modeling of Materials, Structures, and Mechanisms

- Ballistic Performance Data and Ballistic Computations

- Autonomy and Precision Targeting Software

Small Arms Fire Control and Advanced Technology

- End to End Optical System Design

- Optical Component Test and Evaluation

- Small Arms Weapon Mounted Targeting System Integration

- Remote Weapon Station System Integration

- Target State Detection and Tracking

- Remote Weapons Software

Firing Tables and Ballistics

- Fire Control Ballistic Data and Products

- Aeroballistics

- Ballistic Software Development

FACILITIES

- Advanced Concepts & Technology Demonstration (ACTD) Laboratory

- Collaboration Innovation Laboratory (CIL)

Firing Tables and Ballistics Division of Fire Control Systems and Technology Directorate

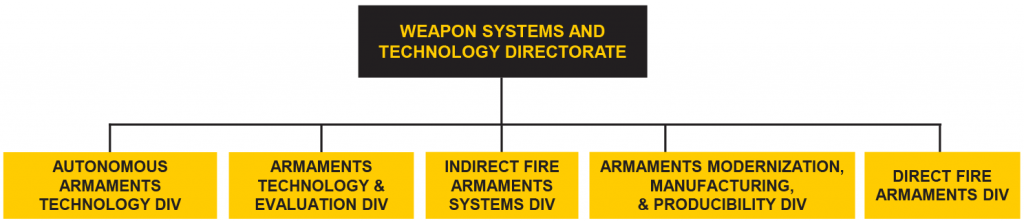

WEAPONS SYSTEMS AND TECHNOLOGY DIRECTORATE

The Armaments Center’s Weapon Systems and Technology (WS&T) Directorate manages and executes science and technology, life cycle engineering, production support, field support and industrial base support for small/medium/large -caliber direct fire and indirect fire (cannon and mortar) armament systems, including system/platform integration, multi-domain armament systems, traditional aviation and Unmanned Aerial Systems (UAS) armament systems, counter UAS armament systems and active protection systems, autonomous/semi-autonomous/remotely-operated armament systems (ground and air), non-lethal armament systems, and directed energy armament systems, including their subsystems, associated equipment, and training devices. WS&T’s competencies include concept development, design, modeling, simulation, analysis, prototype, fabrication, integration and testing of the armament systems mentioned above as well as the associated enabling technologies such as turrets/cabs, automated ammunition handling systems, recoil systems, gun mounts, weapon actuation and motion control, equilibration systems, gunner protection solutions and laser ignition systems. The Weapon Systems and Technology Directorate is a world leader in weapons engineering, employing our subject matter expertise and labs – in collaboration with our industry partners – to rapidly innovate, advance the state-of-the-art for Armaments Systems and accelerate the fielding of critical capabilities and technologies to the Warfighter.

CORE TECHNICAL COMPETENCIES

Armament System & Subsystem Design

- Small/Medium Cal, Artillery, Tank, and Mortar Systems

- Munitions Handling

- Turret/Cab Components

- Mounts, Recoil Mechanisms, Equilibrators, Elevation Drives & Traverse Mechanisms

- Force Protection Armaments & Technologies

- Remote/Robotic Armaments and Control Mechanisms

- Automation/Autonomy

- Aviation & Weaponized UxVs

- Advanced unmanned systems payloads (sensors, weapon systems, etc.)

- Autonomous collaborative technologies

- Directed Energy & Non-lethal

Armament Integration

- Human Machine Integration

- Platform integration (including Cannon, Mount, Ammo Handling, Fire Control, Cab/Turret, Remote Weapons Station (RWS) Physical and Computer Aided

- C-UAS and Gun Based Air Defense

Manufacturing Technologies

- Process and Material

- Product Engineering

- 3D Technical Data Packages

- Additive Manufacturing

- Force Protection Uncrewed Aerial Systems development

- Force Protection UXS Algorithms

Armament Technical Expertise

- Fatigue and Fracture of Materials

- Modeling & Simulation (Solid, Structural, Thermal, Fluid Dynamics)

- Performance Coatings

- Scalable Effects

FACILITIES

- Armaments Technology Facility

- Col. John M. McHugh Armament Integration Facility

- Directed Energy Laboratory

- M119 Digitization Laboratory

- Medium Caliber Integration Lab

- Mounted Mortar and Automation Laboratory

- Production Integration Laboratory

- Remote Weapons Laboratory

- Simulated Weapon Environment Testbed (SWeET) Laboratory